Marshall Industrial Technologies has been serving clients for seven decades and understands the changing needs of the industrial community. In our 30,000-square-foot machine shop, we’re equipped with machinery and technical skills to meet those needs, and our team of machinists and fabricators operate 24 hours a day, seven days a week to provide efficient service. We manufacture replacement and spare parts, often more quickly than the original manufacturer can have them delivered to you.

We’re proud to offer a wide range of machine shop fabrication services and deliver high-quality custom solutions.

Machining vs. Welding & Fabrication

Machining vs. Welding & Fabrication

It’s important to note the difference between machining, welding, and fabrication. The production processes themselves are distinct, and they start with differently shaped materials and finish with different levels of precision. With machining, pieces are taken away from the starting material; with fabrication and welding, pieces are added to the material.

All types of metals are used in both processes. For ceramics and most plastics, machining is the best option, while fabrication is effective for non-ceramic composite materials. Additional materials like glass or plastic may be added later to the finished product via a different process.

Machining

Machining

Material is removed from a solid round bar, tube, or plate via a variety of processes, including milling, drilling, and turning. Machining offers greater precision than fabrication—CNC machined parts can have tolerances as small as +/- 0.0002. Our machining services include:

- Turning: up to 60 inches in diameter on our 24′ engine lathe or up to 6 feet in diameter on vertical turret lathe

- Line Boring: up to 10 tons on our vertical turret lathe

- Surface & Blanchard Grinding: up to 48 inches in diameter

- Broaching: up to 2 inches wide by 10 feet in diameter

- Milling

- Drilling

Fabrication

Fabrication

With metal fabrication, techniques such as bending, punching, cutting, and welding are used to build parts from plate and formed, or expanded materials. CNC precision fabrication allows for tolerances as small as +/- 0.005. Depending upon the application, that may be enough, which is why fabrication is a popular cost-effective choice for certain products on small, medium, and large production runs.

Welding

Welding

With extreme heat and/or the use of other metals or gases, two pieces of metal are joined together. There are a variety of welding processes, including stick welding (SMAW), MIG welding (GMAW), Flux Cored arc welding (FCAW), tungsten inert gas or Tig welding (GTAW) and Orbital Fusion welding.

Machine Shop & Fabrication Services From Marshall Industrial Technologies

Machine Shop & Fabrication Services From Marshall Industrial Technologies

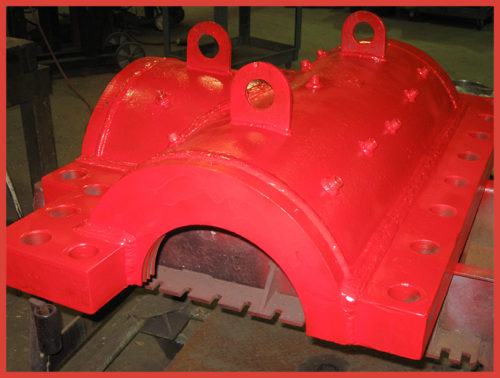

The Marshall Industrial Technologies Machine Shop and Fabrication Services Division features A.S.M.E. Code-qualified welders, fabricators, machinists and machinery rebuilders, and so much more. We specialize in repairing, refurbishing, and modifying equipment—quickly, precisely, and cost-effectively.

We offer the following welding and fabrication services:

- A.S.M.E. Code “U” & “S” Stamps

- National Board “R” Stamp

- Pressure Vessels

- Fabricated Components

- Piping Systems

- Leak Sealing Enclosures

- Weld Repairs

- Weld Buildup

- Hardfacing Weld Metal Overlay

- Corrosion Resistant Weld Metal Overlay

- CNC Thermal Shape Cutting

- Plasma Cutting

Replacement and Spare Part Manufacturing

Replacement and Spare Part Manufacturing

Don’t wait to hear from the original manufacturer when you can have your spare parts in hand much more quickly. We offer replacement and spare part manufacturing for:

- Shafts

- Rolls/Rollers

- Bronze & Babbitt Bearings

- Trunnions

- Housings

- Frames

Custom Precision Repair and Machinery Modification

Custom Precision Repair and Machinery Modification

This is a small selection of the type of machinery we can repair or modify:

-

Banbury Mixers

- Shakers

- Crushers

- Blenders

- Pumps

- Heat Exchangers

- Power Transmission Equipment Presses

- Gear Boxes

- Mill Equipment

- Extruders

- Compressors

- Blowers

- Calenders

Dismantling and Reassembling

Dismantling and Reassembling

Whether you’re moving to a new location or rearranging your space to allow for new equipment or processing, expert dismantling and reassembly of your equipment can make the move faster and easier.

- 200-ton Horizontal Forcing Press

- 10-ton Material Handling Capabilities

- Equipment Removal, Repair and Installation

Founded in 1951—and employee owned and operated since 2017—Marshall Industrial Technologies brings 70 years of experience and dedication to machine shop fabrication as well as HVAC, electrical, plant maintenance, and more. Staying on top of trends and emerging technology has enabled us to adapt to meet our customers’ needs over the years, and we remain committed to ongoing growth and development. Contact us to learn more about high-quality custom products and how we can help with your next project.