Marshall Industrial Technologies uses state-of-the-art infrared thermography technology to conduct infrared electrical inspections on components to identify issues before they can cause problems. The process is both safe and economical and is highly recommended by both the National Fire Protection Agency (NFPA) and the American Society of Non-Destructive Testing as an ideal means of testing the safety and effectiveness of components.

Importance of Infrared Thermography Inspection

Importance of Infrared Thermography Inspection

Infrared thermography inspection uses directed heat to find weaknesses and failures in components. Since unexpected failures can result in dangerous and costly system failures, it is critical to locate and address component defects early in the manufacturing process. For this reason, infrared electrical inspection is incorporated into the manufacturing process for a variety of products, including:

- Electrical Control Systems

- Electrical Disconnect Switches

- Lighting Panels

- Pole Connections

- Electrical Outlets and Receptacles

- Switches and Transformers

- Utility Substations

- Mechanical Applications

- Tank Repair

Advantages of Infrared Thermography

Advantages of Infrared Thermography

Infrared thermography offers several advantages, including:

- Non-contact testing for enhanced safety

- Two-dimensional thermal imaging for easy visual comparison

- Real-time, high-speed scanning

- Safe and effective testing method

- Non-invasive and non-destructive

Infrared electrical inspection offers a variety of benefits over more traditional testing methods, including:

- Reduced repairs and downtime

- Increased equipment service life

- Fewer service interruptions

- Reduced safety risks

- Lower repair and maintenance costs

- Increased productivity

- Prevented system failures

- Reduced losses

- Lower insurance costs

Outside the Box Uses in the Industrial Space

Outside the Box Uses in the Industrial Space

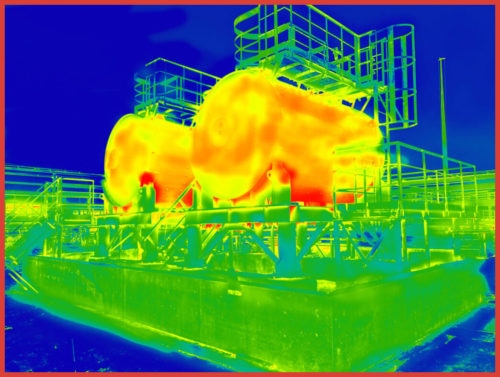

Marshall was one of the early pioneers to use infrared thermography to assist in the diagnosis of leaks in jacketed tanks. With no direct access to the inner tank wall, the jacket of the tank is scanned and the temperature information used to greatly narrow down the region of the leak. The resultant repair requires a much smaller breach in the outer jacket and results in a better, more economic repair.

Partnering with Marshall Industrial Technologies for Infrared Thermography Services

Partnering with Marshall Industrial Technologies for Infrared Thermography Services

When you partner with Marshall Industrial Technologies for your infrared thermography services, you benefit from the latest technology wielded by skilled and experienced technicians. All of our technicians are fully trained and certified to conduct and analyze the results of infrared electrical inspections.

Marshall’s state-of-the-art infrared inspection technology allows us to preemptively identify a variety of issues in mechanical systems, including bearing friction, scaling and wear on heater rolls, thinning or defective vessel and pipe insulation, tank leaks, and hot and cold spots in HVAC systems.

Our inspection reports are comprehensive, and include:

- Full-color infrared images

- Detailed interpretation of the images and collected data

- Complete summary of findings

- Our expert recommendations for corrective action

Reach Out to Our Infrared Thermography Experts Today!

Reach Out to Our Infrared Thermography Experts Today!

At Marshall Industrial Technologies, we ensure safe, cost-effective operations for everything from process piping and mechanical systems to HVAC and electrical systems. Being in the industry for 70 years, we have the unique experience and hands-on knowledge necessary to conduct thorough infrared thermography inspections, electrical work, machinery repair, and equipment installation for virtually every industry.

We specialize in the installation, repair, and maintenance of equipment in highly regulated industries, including chemical processing, pharmaceutical manufacturing, food and beverage production, and industrial manufacturing. We maintain stringent policies and procedures concerning safety in every aspect of our operations, including confined spaces, lock-out/tag-out, hot work, and opening process systems. Our dedication to safety is reflected in our insurance Experience Modification Rating (EMR) and also by our OSHA 300 frequency statistics, which greatly exceed industry standards.

To learn more about Marshall Industrial Technologies Infrared Thermography Inspection services and other safety solutions, contact our experts today to request a quote.