At Marshall Industrial Technologies, our mechanical services group specializes in helping customers keep their operations up and running with high efficiency and without unplanned downtime. We offer a broad selection of installation, maintenance, and repair services that are available 24 hours a day, seven days a week, which enables us to serve as a single source for all scheduled and emergency capital project and plant maintenance needs. Below, we highlight our mechanical service offerings.

Machinery Installation/Plant Relocation/Machinery Repair

Machinery Installation/Plant Relocation/Machinery Repair

Proper planning and execution of Machinery installation is critical in both the construction of a new facility and the relocation and updating of an existing plant. It can involve a variety of steps, from creating a support structure to installing piping and wiring, depending on the type of machine installed and the condition of the installation site.

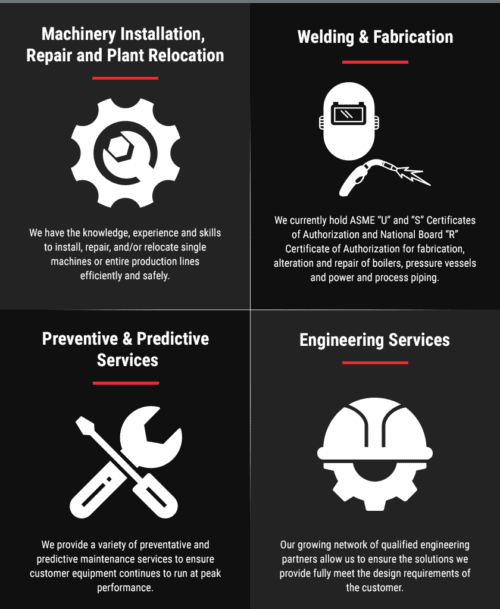

Regardless of the size of the project, the team at Marshall Industrial Technologies is ready to provide customers with integrated/turnkey industrial equipment installation solutions. We have the knowledge, experience and skills to install, repair, and/or relocate single machines or entire production lines efficiently and safely. Our capabilities include:

- Machine foundation

- Rigging

- Millwrighting

- Machinery alignment

- Pipefitting for complete piping systems

- Electrical service and process controls installation

- Machinery Repair services

- Machinery start-up support

Welding & Fabrication

Welding & Fabrication

Fabrication is a broad term that encompasses all of the industrial processes used to turn raw or partially finished materials into finished parts and products. One of the most commonly used fabrication processes is welding, which utilizes heat and pressure to join individual components (e.g., fittings and frame pieces) together.

The welding and fabrication professionals at Marshall Industrial Technologies are ASME Code qualified. We currently hold ASME “U” and “S” Certificates of Authorization and National Board “R” Certificate of Authorization for fabrication, alteration and repair of boilers, pressure vessels and power and process piping.

Our welding and fabrication capabilities include:

- Structural steel fabrication

- Custom fabricated and machined components

- Pressurized component fabrication, alteration and repair

- Sanitary process piping system design and construction

- Welding processes include SMAW, GMAW, GTAW, FCAW, and Orbital Fusion welding

- Hard facing and corrosion-resistant overlay

- CNC thermal shape cutting

- Plasma cutting

Preventive & Predictive Services

Preventive & Predictive Services

Preventive & Predictive Maintenance planning and implementation is essential to keeping any facility equipment running smoothly. While there are several maintenance strategies available, the two most effective are preventative and predictive. Preventative maintenance involves performing maintenance on a regular schedule, regardless of whether or not it is actually needed. It helps keep machines in repair but does not take into account the current condition of the machine. Predictive maintenance involves performing maintenance as needed. It uses technology to collect and analyze machine condition in real-time to stop potential problems before they can occur.

The Marshall team provides a variety of preventative and predictive maintenance services to ensure customer equipment continues to run at peak performance and customer operations do not experience any delays. These include:

- Machinery inspection and troubleshooting

- Machinery alignment

- Ultrasonic thickness testing

- Hydrostatic testing

- Dye penetrant testing

- Laser shaft alignment

- Overhead crane repair

Engineering Services

Engineering Services

In addition to our machinery installation, welding and fabrication, and maintenance capabilities, our growing network of qualified engineering partners allow us to ensure the solutions we provide fully meet the design requirements of the customer. Regardless of the size or complexity of the project, we can provide the following services:

- Mechanical engineering

- Civil engineering

- Structural engineering

- Electrical engineering

Partner With Us for Your Mechanical Service Needs Today

Partner With Us for Your Mechanical Service Needs Today

Both inefficient operations and unplanned downtime can negatively affect the productivity and profitability of your facility. The Mechanical Services Group at Marshall Industrial Technologies focuses on keeping your operations running at peak performance. Whether you need to modernize your facility, install and repair equipment, or perform general maintenance, we are here to help.

Our technicians are fully trained satisfy your industrial installation, maintenance, and repair needs. Our roster of skilled tradesmen includes:

- Millwrights

- Pipefitters

- Welders

- Fabricators

- Riggers

- HVAC-R Technicians

- Electricians

- Machinists

To learn more about our mechanical services, contact us today. To discuss your needs with one of our representatives, request a quote.