When your equipment breaks down due to a component failure, shipping your part off for repairs can take weeks or months. For critical operations, this kind of downtime is simply not feasible. Instead of sending your part to an off-site machinist for repair or replacement, you can partner with an on-sitemachining service who will conduct repairs right at your facility. Marshall Industrial Technologies offers on-site machining services that bring the machining equipment to your worksite, so you can save both time and money.

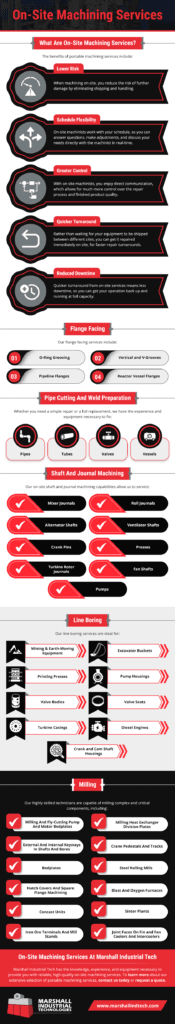

What Are On-Site Machining Services?

What Are On-Site Machining Services?

On-site machining services, also known as portable machining services, are critical for correcting field equipment breakdowns. With on-site machining, you are no longer subject to the vagaries of shipping lines and third-party wait times. You receive top-quality, accurate machining services right at the site of the breakdown. The benefits of portable machining services include:

- Lower Risk. When machining on-site, you reduce the risk of further damage by eliminating shipping and handling.

- Schedule Flexibility. On-site machinists work with your schedule, so you can answer questions, make adjustments, and discuss your needs directly with the machinist in real-time.

- Greater Control. With on-site machinists, you enjoy direct communication, which allows for much more control over the repair process and finished product quality.

- Quicker Turnaround. Rather than waiting for your equipment to be shipped between different sites, you can get it repaired immediately on site, for faster repair turnarounds.

- Reduced Downtime. Quicker turnaround from on-site services means less downtime, so you can get your operation back up and running at full capacity.

Flange Facing

Flange Facing

Marshall Industrial Technologies offers a variety of on-site machining services. Flange facing is one of our most popular services. We provide quick, seamless flange repairs and maintenance that help to prevent leaks due to damaged, worn, or corroded flanges. Our on-site machinists specialize in full-face, back-face, grooved, and raised-face flanges up to 120″ OD.

Our flange facing services include:

- O-Ring Grooving

- Vertical and V-Grooves

- Pipeline Flanges

- Reactor Vessel Flanges

Pipe Cutting and Weld Preparation

Pipe Cutting and Weld Preparation

We offer extensive on-site pipe cutting and weld preparation, for speedy pipe system repairs. We can cut and bevel pipe to remove damaged sections, assist with pipe demolition, install brand new piping, and weld pipes and fixtures as necessary. Whether you need a simple repair or a full replacement, we have the experience and equipment necessary to fix:

- Pipes

- Tubes

- Valves

- Vessels

Shaft and Journal Machining

Shaft and Journal Machining

At Marshall Industrial Technologies, we know that downtime can have severe effects on your productivity and profitability. Our shaft and journal machining services help you restore critical equipment to get your production line back up and running at full capacity. We can assist with every aspect of repair for shafts and journals up to 11″ diameter, including ring grooves, parallel shafts, stepped profiles, welding, and polishing. Our on-site shaft and journal machining capabilities allow us to service:

- Mixer Journals

- Roll Journals

- Alternator Shafts

- Ventilator Shafts

- Crank Pins

- Presses

- Turbine Rotor Journals

- Fan Shafts

- Pumps

Line Boring

Line Boring

We have extensive line boring capabilities for holes between 1″ and 36″ in diameter that are between 60″ and 12′ apart. Our state-of-the-art boring equipment allows us to enlarge and repair bores in both cylindrical and flat surfaces to ensure optimal bearing alignment and rotation. Our line boring services are ideal for:

- Mining & Earth-Moving Equipment

- Excavator Buckets

- Printing Presses

- Pump Housings

- Valve Bodies

- Valve Seats

- Turbine Casings

- Diesel Engines

- Crank and Cam Shaft Housings

Milling

Milling

For precision components, we use highly-calibrated on-site milling machines for extremely accurate multi-axis machining. Our highly skilled technicians are capable of milling complex and critical components, including:

- Milling And Fly-Cutting Pump And Motor Bedplates

- Milling Heat Exchanger Division Plates

- External And Internal Keyways In Shafts And Bores

- Crane Pedestals And Tracks

- Bedplates

- Steel Rolling Mills

- Hatch Covers And Square Flange Machining,

- Blast And Oxygen Furnaces

- Concast Units

- Sinter Plants

- Iron Ore Terminals And Mill Stands

- Joint Faces On Fin and Fan Coolers And Intercoolers

On-Site Machining Services at Marshall Industrial Tech

On-Site Machining Services at Marshall Industrial Tech

For more than 70 years, Marshall Industrial Tech has been a leading provider of emergency repair and replacement services for customers in a variety of industrial settings. Whether you need equipment maintenance, repair, or replacements, Marshall Industrial Tech has the knowledge, experience, and equipment necessary to provide you with reliable, high-quality on-site machining services. To learn more about our extensive selection of portable machining services, contact us today or request a quote.