Unscheduled outages in production can cause roadblocks that impact the entire supply chain. Effective plant maintenance services increase equipment uptime in a manufacturing facility by applying best practices to generate better asset reliability. By ensuring that equipment consistently functions as expected, manufacturers can avoid unplanned, costly downtime. Ultimately, conducting proactive plant maintenance allows a plant to run more efficiently, which translates to reduced costs and improved profitability.

Marshall Industrial Technologies’ Plant Maintenance Services

Marshall Industrial Technologies offers a wide range of maintenance solutions to help factories operate consistently and efficiently. Our many solutions can support routine, spot, and emergency maintenance at your plant, including the following:

- Electrical maintenance and installation

- Instrumentation and process controls

- Mechanical maintenance and installation

- Millwright services

- Pump maintenance

- Rigging services

- Welding and fabrication work

- Process and utility piping installations and modifications

- ASME code pressure vessel, boiler, and piping repairs and alterations

- On-site/portable machining services

- Predictive and preventive machinery maintenance

- Preventive HVAC maintenance contracts

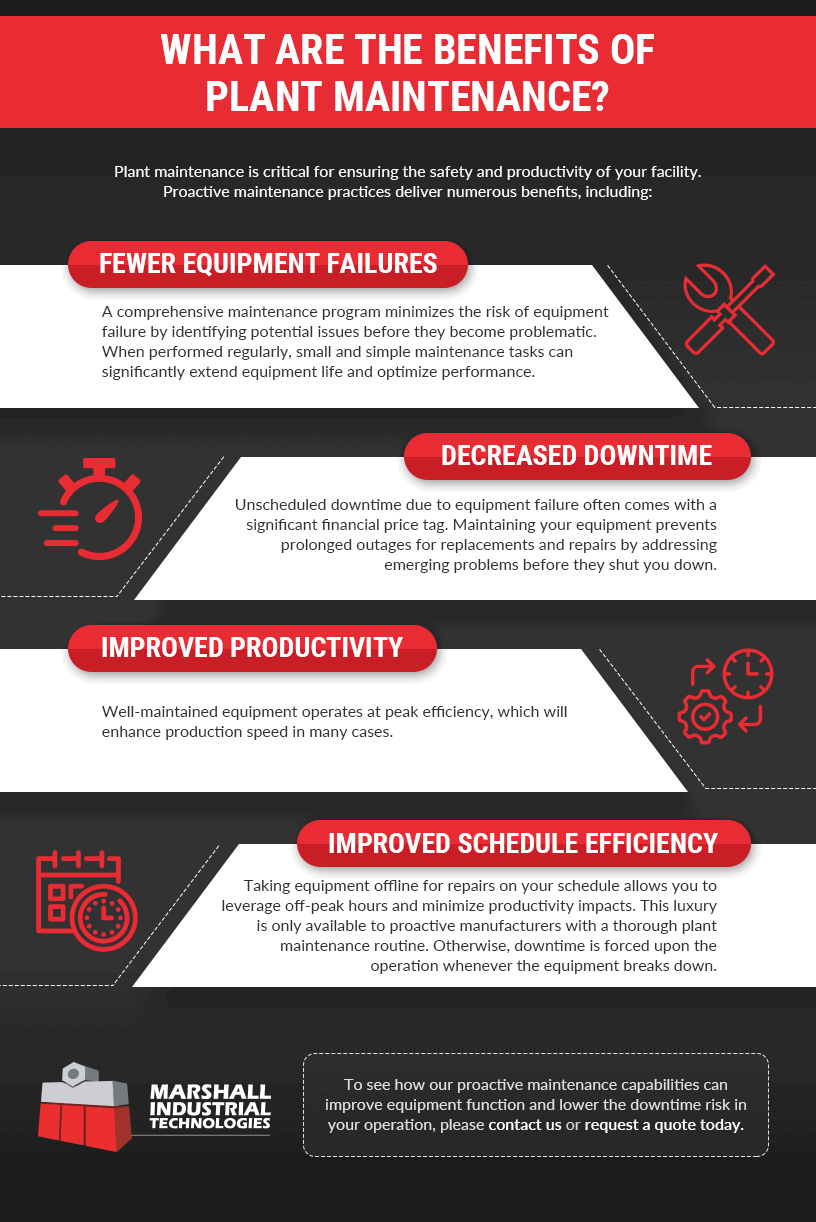

What are the Benefits of Plant Maintenance?

Plant maintenance is critical for ensuring the safety and productivity of your facility. Proactive maintenance practices deliver numerous benefits, including:

- Fewer equipment failures. A comprehensive maintenance program minimizes the risk of equipment failure by identifying potential issues before they become problematic. When performed regularly, small and simple maintenance tasks can significantly extend equipment life and optimize performance.

- Decreased downtime. Unscheduled downtime due to equipment failure often comes with a significant financial price tag. Maintaining your equipment prevents prolonged outages for replacements and repairs by addressing emerging problems before they shut you down.

- Improved productivity. Well-maintained equipment operates at peak efficiency, which will enhance production speed in many cases.

- Lower repair costs. Failing to implement a plant maintenance program dramatically increases the risk of catastrophic failures. Comprehensive plant maintenance services minimize repair costs by resolving minor problems before they cause breakages or component failures.

- Improved Schedule Efficiency. Taking equipment offline for repairs on your schedule allows you to leverage off-peak hours and minimize productivity impacts. This luxury is only available to proactive manufacturers with a thorough plant maintenance routine. Otherwise, downtime is forced upon the operation whenever the equipment breaks down.

Leveraging the Latest Technology for Plant Maintenance Services

Since 1951, Marshall Industrial Technologies has been providing high-quality, reliable plant maintenance services. We strive to reduce your total maintenance spend through a combination of technology, experience, and skill. Our highly trained maintenance technicians will conduct routine maintenance, preventative services, emergency repairs, planned shutdowns, or periodic maintenance. With our team handling maintenance, your team gains the freedom to focus on core facility tasks, such as production and customer service.

We also supply any necessary supervision, parts, equipment, tools, and materials required to complete the job. Whether your detailed maintenance plan involves mechanical, electrical, rigging, piping, millwright, or fabrication work, we will complete it on time and by the highest quality standards.

At Marshall Industrial Technologies, we have more than 70 years of experience providing our customers with a broad range of maintenance and repair services. Our customers rely on our advanced technologies, machinery knowledge, and comprehensive capabilities to stay competitive in their target markets and achieve equipment compliance with stringent safety and environmental regulations.

To see how our proactive maintenance capabilities can improve equipment function and lower the downtime risk in your operation, please contact us or request a quote today.